Porcelain Insulator News

By Elton Gish

Reprinted from "Crown Jewels of the Wire", October 2005, page 15

This month we will update you on a few interesting "finds" and

reports. The insulators covered will be both unipart (U-numbers) and multipart

(M-number)

styles. To start, I thought it would be worthwhile to discuss briefly the use of

Jack Tod's U-Chart as found in his book, Porcelain Insulator Guide Book. This is

the primary reference for unipart insulators. In addition to the U-Chart, the

book provides a detailed description of how insulators were made, manufacturer's

history, and markings that can be found on unipart porcelain insulators.

Many

people find using the U-Chart difficult. Most of these problems come from not

understanding what the U-Chart is actually showing you and how to use it. There

are relatively few CD numbers for glass insulators. Variations in a particular

basic style (like signal, beehive, etc.) are not assigned a different CD, but in

porcelain, a new U-number is often assigned when the differences are

significant. Often the differences are characteristic of a specific manufacturer

or identifies the dry process porcelain version. One exception is when the

difference is primarily due to the trimmer operation that cuts the profile.

Porcelain insulators are not pressed out in a mold, as were glass insulators.

The only exceptions are when the complete shape of the insulator (with cable

groove and/ or tie-wire groove) is cast in a mold or pressed in a two-part or

three-part mold. The later method was usually for dry process insulators and

certain smaller wet process porcelain styles made by Fred Locke and Pittsburg,

which usually have visible mold lines through the tie-wire groove or mold line

over the dome. Porcelain insulators that do not have mold lines had the profile

cut out by an operator manually swinging a shaped trimmer blade up against the

clay body as it rotates on a turntable. The trimming operation took no more than

one second.

The variability in profile of a specific insulator style could be

quite significant when you consider there could be different trimmer operators

and multiple trimmer lines. Additional variations in profile can occur when the

trimmer blade becomes worn, new trimmer blades or made, the mechanism that

swings the trimmer blade against the insulator becomes worn or misaligned, the

young trimmer's helper didn't set the clay body in the center of the turntable,

and probably other problems we haven't imagined. Then there are profile

differences between months or years of production and between different

manufacturers.

The greatest variability in profile, and consequently the most difficult area

in the U-Chart for collectors, is the section that covers the "signal"

style - U-228 to U-326. The next difficult area covers the small cable-top styles

- primarily U-438 to U-488.

Most people do not know that Jack Tod did NOT set up

the U-Chart from actual specimens, but rather from manufacturer's catalog

drawings. He did make drawings from actual specimens that were not represented

in catalogs he had available. Actual insulators produced by a specific company

did not necessarily match the catalog drawing profile very closely, especially

in the early years before the early 1920's. During this period manufacturers

could not turn out insulators fast enough and they had little concern over

producing a consistent product.

Remember, the dimensions shown for a specific

U-number can easily vary by +/- 1/4" and larger amounts as the size of

the insulator increases. Most of the questions I get concerning problems with

matching specimen in hand with the U-Chart is that the dimensions do not match.

The truth is the dimensions rarely will match exactly due to the reasons

explained above.

The primary thing you should look at when trying to identify and label your

insulator with the correct U-number is to determine the following in this order

(in declining importance):

- basic style (pony, exchange, signal, tramp,

cable-top, etc.

- single / double (1 inner skirt) or triple (2 inner skirts)

petticoat

- extended, flush or recessed inner skirt

- flat top, rounded, or

other shape of dome or crown top

- thickness (height) of the lower skirt

- profile of the lower skirt (slanted, vertical, rounded)

- cable groove or

tie-wire groove width

- upper wire ridge profile and thickness

|

Putting all this in words sounds complicated. It is about the same thing you

do to ID a CD number, just you have fewer CD numbers to select from. There are

over 1000 U-numbers. The U-Chart is logically laid out in order of basic styles:

pony, exchange, mine, tramp, signals, cable-tops without petticoats, double

petticoat, triple petticoat, high-tops, side petticoats, large styles, with the

last section reserved for glazeweld, very early classics, and threadless. If you

find a U-number close to what you have, do not get frustrated that it doesn't

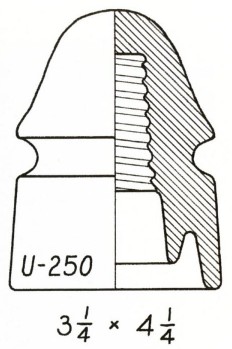

match exactly, because odds are few insulators will match exactly. For example,

the photo of two U-250's illustrates the variability introduced by the trimming

operation. Note the differences between the two insulators compared with the

U-number drawing. If you think the variability is too great, simply call it

Sim-U-250. That is close enough. If you give that description to someone else or

put it on a sale list, others will know pretty much what you are talking about.

|

|

|

Two U-250's showing variability due to trimming. |

Now to something more interesting n the new reports. Marty Caverly sent the

following photo of his U-239 and U-191. These were made of dry process porcelain

by R. Thomas & Sons Co. circa 1910. The glaze is a greenish gray in the

thicker areas and the tops of the domes are "carved". Actually the top

of the mold was carved, which leaves multiple flat areas as if the insulator

itself was carved. This is a characteristic of Thomas dry process porcelain made

through the 1910's. Both insulators were made in a 3-part mold. The body of the

insulator with side cable groove was made in two halves of the mold with the top

up from the upper wire ridge being the third part. I have one specimen of U-239

with almost no color in the glaze. Some specimens have a much more pronounced

green color. Note the crude, porous nature of the porcelain. There are several

"carved-top" styles. The greenish-gray U-191 is the rarest with less

than 10 reported. Most have been reported coming out of Michigan.

Unmarked greenish-gray Thomas U-239 and U-191.

Apparently Locke was trying to compete with the cheap line of Thomas-made dry

process insulators. Ken Willick reported finding a broken specimen of U-169 in

the Victor dump. It was made of dry process porcelain with the large incuse

Victor R=oo insulator logo marking and the glaze was bluish-gray.

|

|

|

Bluish-gray U-169 found in the Victor dump. Note the very porous dry process

porcelain. |

If you missed the San Jose National show this year, you missed a wonderful

display by Barbara Smith and Carver Mead. Their collaborator, Alonso Rodriguez,

recovered two incredible multiparts from the Guanajuato line in Mexico. The line

was constructed in 1903 using Fred Locke M-3725's. The top insulator on the

towers was vulnerable to lightning damage. The line was upgraded in 1906 by

moving the top insulator below the double crossarm and running a grounded wire

at the top. The insulators were also replaced with larger Thomas 3-part

insulators. Alonso recovered one M-3990 (18 - 13 - 11 x 20.5) and one similar

insulator that was assigned a new M-number. No specimens of either insulator

have ever been reported. M-3990 was shown in the early Thomas catalogs. The new

style is M-3940 (15 - 12.5 - 10.5 x 20). Note the smaller diameter top shell

with unique style of crown that appears to be an improvement over M-3990 by

strengthening the crown to make it less prone to damage. Both insulators have

the period Thomas glaze that is reddish brown with drippy mustard in places. The

top shell of M-3990 is mostly mustard colored!! The bottom two shells are nearly

the same.

|

|

|

Thomas M-3990 and M-3940 from the Guanajuato line in Mexico. |

You probably think that only glass insulators have drip points. Bet you

didn't know that some porcelain insulators had drip points, too. How about a

Fred Locke U-608A with "drip points"? Bill Rohde proudly displayed

this unique specimen at the San Jose National. There are five rather large black

"drips" along the outer skirt edge making a nice contrast to the

caramel-colored glaze. I have the cousin to Bill's insulator. My U-608A has the

same glaze coloring, but only one thick, black drip. Do any of you have a

similar insulator with "drip points"?

Fred Locke U-608A with five large, thick, black "drip points".

|